>

Strong & Co Of Romsey, A Brief History……

HORSEFAIR BREWERY…

The Horsefair Brewery had been in operation many years before it was acquired by David Faber. Details of its early history are a little uncertain, but it is known that in the last quarter of the 18th century the partners owning the brewery were Richard Trodd, who was Mayor of Romsey in 1 778, and Thomas Hall I. The Trodds seem to have been the senior partners, and were said originally to have been maltsters at Cupernham.Apparently Thomas Hall I died sometime before 1795, when his share descended to his nephew Thomas Hall II. The latter and Richard Trodd both died in 1796 when the business was carried on by William Trodd, son of Richard, and Sarah Hall, widow of Thomas Hall II. Unfortunately William died in 1803 leaving only minor children, and there was considerable litigation between the heirs of the Trodds and Halls until 1811, when Sarah died. Consequent upon an Order by the Court of Chancery in August 1811, the Trodd interest was bought out, and the brewing business passed into the hands of two brothers, Thomas Hall III and Charles John Hall, the sons of Thomas Hall II. The heir of the Trodds, William Stewart Trodd, the grandson of Richard, having converted his share of the brewery into cash, seems to have decided that money was for spending, and in this was highly successful. Poor William soon found, as did so many before and since his time, that it was much easier to spend money than to acquire it, and after some exciting and hopeful ventures with racehorses, went bankrupt. His love of horses then led him to obtain employment as the driver of a stage coach. But even this did not seem to last very long, and he is said to have ended his days as a gatekeeper in the employ of the London and South Western Railway at Crampmoor Crossing.

The partnership between Thomas and Charles John Hall lasted until Christmas 1834, when the elder brother retired, leaving Charles John Hall as the sole owner of the business. This he carried on successfully until 1858, when he retired and leased the Brewery with 23 licensed houses to Thomas Strong. He retained the ownership until his death in 1870, when his widow Catherine Hall inherited. After her death in 1875 all the properties were sold in that year by her heirs, Charles Loddington Hall and his wife Emily Hall, to Sir Edward Bates M.P. In July 1883 Sir Edward Bates sold the Brewery and attached houses to Thomas Strong, so that once again ownership and occupation were united. Thomas Strong died three years later, and it was then that the Brewery was acquired by David Faber.

>

BELL STREET BREWERY…

The Bell Street Brewery premises were occupied from 1740 to 1819 by three generations of a family named Comley, but it is not certain when they started to brew, as they were originally maltsters. Thomas Comleyy 1st leased the original premises in 1740 from a family named Wale, and purchased them four years later for £267 .10. Od. His son, John Comley, succeeded, and from him the business passed to the grandson Thomas Comley 2nd, who died in 1819. The latter left his property in trust, desiring that the business should be maintained until his children were 21 years of age, when they were to have the option of taking it over. Charles John Hall, as surviving Trustee, continued the business until 1847, although it seems to have been managed by the Southampton Brewer, William Aldridge. When it was found that all the children refused their option of taking over the business, it was sold to Josiah George the younger, who conducted the Brewery until his death in 1862. The business was managed for some time by the Executors, and was eventually acquired by his nephews, William Bentley George the younger and Samuel Cartwright George, who traded under the style of George Brothers. In 1872 Samuel Cartwright George retired, and 14 years later the business was bought by David Faber. The “Comley” ledger formerly preserved at Horsefair, relates to the period 1770-1788 and shows that the Comleys had a considerable trade over a wide area around Romsey – Victuallers at Gosport, Whiteparish, Winchester etc., being mentioned, as well as local notabilities such as Sir Jacob Woolfe at Melchet Park.

>

CRESSEY’S BREWERY…

It is not known when this Brewery was founded, but that there was a Brewery in the Hundred in 1781 maybe seen from an advertisement in the “Winchester and Salisbury Journal”, when it was stated to be lately in the occupation of Messrs. Pulling and Rant, common brewers. This Brewery was said to be near the turnpike gate at the junction of the Winchester an& Botley roads, but whether it was identical with Cressey’s Brewery purchased by David Faber in 1886 is not clear. Cressey’s Brewery was certainly in existence in 1855, when it was owned by Mrs. Sarah Jesser who leased it to her son, Alfred Pitt Jesser and her son-in-law, Francis Cressey. Sarah Jesser died in 1864 and left her interest in equal shares to her son and daughter, but the son died in 1865, and Francis Cressey took over control. After the death of Francis Cressey in 1873, the Brewery was managed by his son, Francis Jesser Cressey, but the death of the latter at an early age, and the litigation among the heirs of Sarah Jesser, led to the sale to David Faber in 1886. It is interesting to note that yet another Romsey brewery was merged with Cressey’s, for in 1855 Jesser and Cressey purchased the “newly erected brewery” of William George Lawes, which was situated in Church Street. This property had an interesting history, for it stood on the site of a former mansion of the Marquis of Lansdowne which had been burned down in 1826, and a malthouse belonging to one William Tarver. The Lansdowne property had been developed by a Romsey brewer, Joseph Humby, but later came into the hands of William Lawes, a maltster, the grandfather of William George Lawes, who greatly extended it. After the purchase by Jesser and Cressey the Brewery became redundant, and was used only as a public house, the “Lansdowne Arms”.

>

The Growth Of Strong’s…….

WEYHILL…

The early development of Strong’s was divided into three main groups, Romsey, Weyhill and Christchurch. Within two years of absorbing George’s and Cressey’s of Romsey, David Faber acquired Gibbon’s Brewery of Weyhill, and a year later King’s Brewery of Christchurch.

Weyhill near Andover was famous for many centuries for its fair, which was referred to as Wy Fair by Piers Plowman, and during Fair time places of refreshment must have abounded. Many of these were temporary booths erected for the duration of the Fair, but being situated at the junction of eight ancient drove ways across the Downs no doubt led to the permanent establishment of inns and alehouses. It is probable that from one of these the original Weyhill Brewery started, although nothing very definite seems to be known about it until a century ago, when it was owned by Charles Child. He sold it in 1878 to a London Distiller, George Gibbons, who pursued an active policy of development. It appears to have been Gibbons who brought into the Weyhill group two smaller local breweries, one at Chilbolton which had been conducted for some years by a family named Tilbury, and the other at East Cholderton, which was owned by a family with the curious name of Wonfor. When in 1888 George Gibbons ran into financial difficulties, his Brewery at Weyhill together with 27 “licensed” houses were purchased by David Faber. Six years later, when Strong’s became a Limited Company, the Weyhill division controlled fifty houses. The old Weyhill Brewery building is still in existence, but it is now occupied as a school.

>

>

CHRISTCHURCH…

The Christchurch Breweries have a long and interesting history, and it is a pity that lack of accurate information makes it difficult to tell the whole story. In the latter half of the 18th century there were two brewing businesses in Christchurch, each with several “licensed” houses. One was conducted by John Cook and the other by William Mitchell and William Wing Mitchell. John Cook appears to have been the most enterprising, and erected a new brewhouse in Dolphin Lane, but after his death some of his houses were sold off in 1793 by his widow, Susannah Cook, to the Mitchells. The Cooks must have been prominent citizens of Christchurch, for one of the Executors of Susannah Cook was George Rose, the famous Secretary of the Treasury who was a faithful friend of Pitt and the “Old George Rose” castigated by Cobbett. The new brewery of John Cook, called the Mansion Brewery, and the remaining “licensed” houses were sold in 1796 to the Portsea Distiller, Sir Samuel Spicer, who conveyed them in 1819 to his brother, John Spicer. Spicer sold out in 1834 to John Peerman, who extended his operations, but went bankrupt. The Mansion Brewery then passed to Henry Rowden who sold it in 1845 to Joseph and James King, they being already established as Brewers in Christchurch. The Kings were originally Brewers in Poole, Dorset, but had moved into Christchurch in 1832 when they purchased the brewery previously owned by the Mitchells. William Wing Mitchell had sold his Brewery in 1796 to John Elliott, who sold in 1814 to Ambrose Daw and William Blake. It was the latter’s successor, Thomas Daw, who sold in 1832 to the brothers Joseph and James King of Poole. James King moved to Christchurch to manage the Christchurch side of the business, and by the absorption of the Mansion Brewery in 1845, the Kings established themselves as the leading local Brewers. Both the brothers died in 1852, when the Christchurch business passed to Joseph King, son of James King. For thirty years Joseph King conducted it, but dying unmarried in 1882, control passed to his half brother, John King, who bought out the interests of his brothers and sisters. Nine years later he sold to David Faber.

>

WETHEREDS, 1945 to 1969…

In 1949 Strong’s business was further strengthened by the acquisition of the well-known brewers Thomas Wethereds & Sons Ltd., a Company which (like Strong’s itself) dates back to the 18th Century. Wethereds Marlow Brewery is thought to have been built in 1758. It was not, however, acquired by Thomas Withered (who had inherited his father George’s brewing business at Marlow) until 1788. That was the year when Thomas leased from one William Clayton premises described as “formerly Miss Freeman’s Boarding School and the Three Tunes Tavern”. Eight years later, when Thomas bought the freehold, mention is made of a “new brewhouse”. That was the start of the business which was to grow into Thomas Wethered & Sons Ltd. The sons were Owen and Lawrence William, who carried on the brewery after Thomas’s retirement in 1845. He died four years later. The business stayed in the hands of the family until it became a limited liability company in 1899, with Owen Peel Wethered, a grandson of Thomas, as Chairman. The start of the 20th century saw big developments in Wethereds. A new bottlery, fermenting room, chimney shaft and electric light plant were installed. Mechanical transport by small steam traction engines towing trailers was instituted in 1905, and six years later petrol lorries were introduced. Over the years, Wethereds expanded and took in other breweries. Birds of Reading was acquired in 1913, adding nine licensed houses to Wethereds properties, and in 1927 Williams’ Royal Stag Brewery at Wooburn, with 35 licensed houses, was bought.The 1949 merger with Strong’s was followed a year later by the acquisition of Stranges’ Aldermaston Brewery, with about 50 licensed houses. In 1953 Higgs Lion Brewery at Reading was acquired, adding a further eight licensed houses.

>

MEW LANGTON…

The final addition to the Strong’s group came in 1965 with the purchase of W. B. Mew, Langton & Co. Ltd., of Newport, Isle of Wight. The Mew family were brewers at Newport from the early 17th century, and by the end of the 18th, Mew & Co. owned prosperous breweries both at Newport and Lymington, Hants. They had a large Army canteen trade, and extended their branches to Aldershot, London, Malta, and the Mediterranean, and even to India and China. In the 19th century Walter Langton became a partner of the Mew Brothers, William Baron and Joseph, and Charles Templeman Mew, William Baron Mew’s eldest son. The final accolade for the firm came in 1850 with the granting of a Royal Warrant to supply Queen Victoria when she was in residence at Osborne.

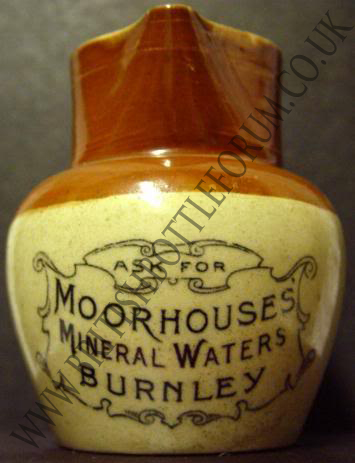

The firm became a limited liability company in 1887, and continued to expand. A new malthouse was built in 1898, with the latest method of pneumatic malting, and the manufacture of mineral waters was begun in a brand new factory. After the First World War further expansion took place, bringing new houses and plant, and adding a tobacconist’s business in 1931. When Mew, Langton merged with Strong’s in 1965, it brought the groups total of licensed houses to 920. The Chairman of Mew, Langton & Co. Ltd, Lt. Col. Francis T. Mew, M.A., T.D., L.R.I.B.A., became a Director of Strong’s in 1965.

>

THE END OF AN ERA…

On Friday 26th June 1981 an era came to an end. At approximately 5.45 am 36 quarters of ABM malt were mashed and the final brew at the ROMSEY brewery was begun. Ironically it was not Strong’s Special Ale or Black Bess stout not even Strong Country Bitter but the ubiquitous Whitbread Trophy that was being made. This final brew, Gyle numbers 251 & 252,was fermented in FV’s 35 and 36. The following week it was racked, filtered and kegged. It was the end of an era. All future beers would be brewed at the Portsmouth brewery and the plant at Romsey would subsequently be destroyed. This ended 123 years of constant brewing in Romsey. The site lingered on for about another 5 years taking in rough beer for filtration and kegging. (Bottling had ceased in April 1981). The site finally closed in 1987.

Information taken from http://www.pgsclassof77.co.uk/strongs.htm

Our Other Links